Origin

The bi-directional static load test (abbreviated as BDSLT) was first put forward in the 1982's by J. Osterberg in the US. This method is also called O-cell load test. In China, Southeast University began to study the test method since 1996, and named it as self-balance static load test.

Test Principle

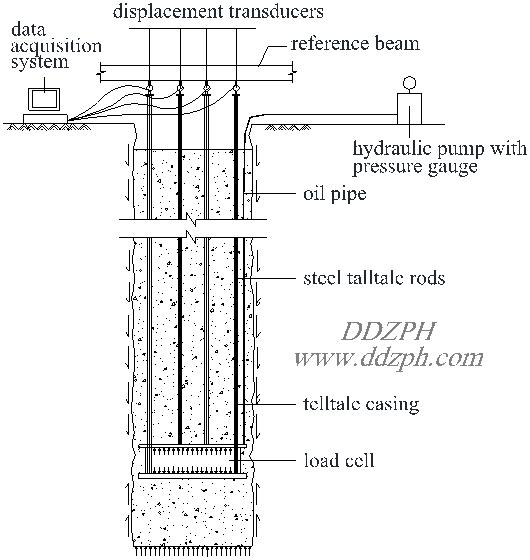

The BDSLT method of pile load test utilizes hydraulically operated Load-Cell embedded inside the concrete of the pile. To determine the position of the load cell, the soil investigation report has to be studied to work out the equilibrium point. The embedded Load-Cell is specially designed using built in hydraulic jacks. Pressure is applied to the load cell by hydraulic oil pump on the ground through the flexible hose embedded into the pile.

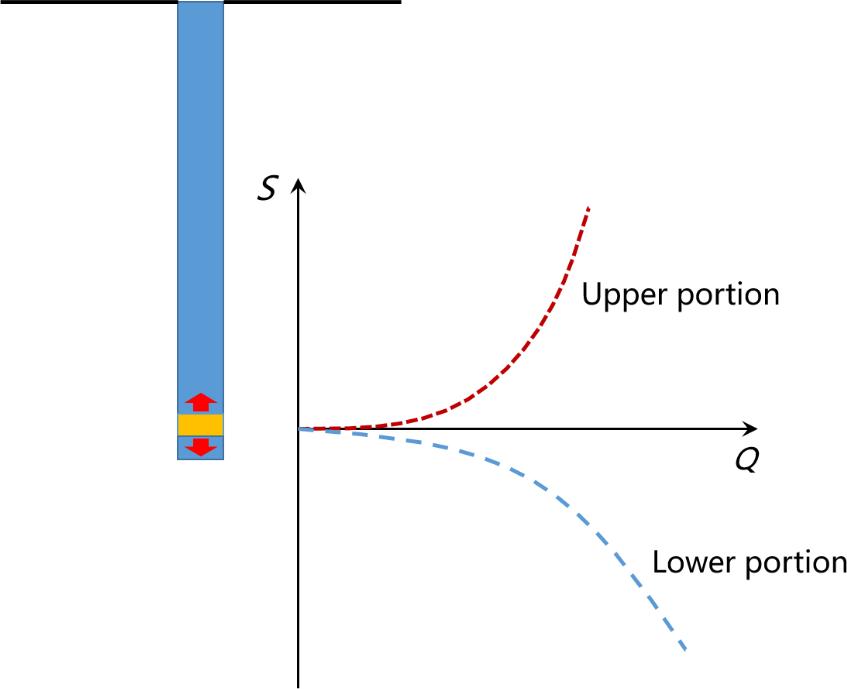

The pressure in the load cell is measured by pressure gauges and the displacements are measured by electronic displacement transducers which are connected to the load cell by telltale rod embedded into the pile. When loaded the load cell expands, pushing the upper shaft upwards and the lower shaft downwards, which would mobilize the side resistance and base resistance of the upper and lower lengths of the pile. According to relationship between the movement and their corresponding S-lgt and s-lgQ curves, bearing capacities of both upper and lower portion of the pile can be determined. Adding up the modified side resistance of upward pile shaft and the base resistance of downward pile shaft makes up the total ultimate bearing capacity of the pile.

Advantages of Bi-directional Method

Compared with the traditional static load test method (pile load method and anchor pile method), the self-balancing pile test method has the following characteristics:

(1) High Test Load Capacity

Currently, the maximum loading value has reached 320MN and multiple cells can be used to test a pile, increasing the test load capacity.

(2) Improved Safety

No reaction system is required as for other static load test. No use of large quantities of girder beams and concrete blocks which could topple if the base is not well prepared.

(3) No Space or Access Problem

Only one high-pressure oil pump and one data acquisition instrument are required for each pile. The test equipment is small in size and light in weight, so that BDSLT can be performed in any site (foundation pit, mountain, under overpasses, underground, or offshore).

(4) Piles with Deep Cut Off Levels

For basement piles, test pile can be performed below ground, eliminating the pile extension to ground level, which saves on construction costs.

(5) Test for Working Piles

With post-grouting techniques, testing of working piles can also be done.

(6) Time Saving

Compared to static load test with test blocks, there is considerable time saving as no pile built up or strip down is necessary. Sometimes multiple piles can be tested simultaneously by using BDSLT method.

(7) Low Expense

BDSLT method is much cheaper than traditional test method.

(8) Applicable to all types of foundations

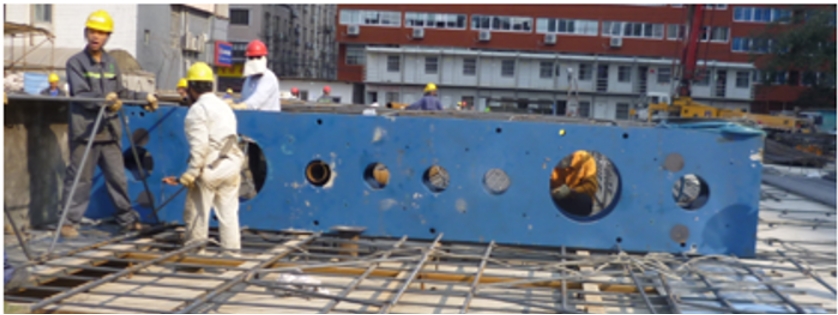

In addition to cast-in-place piles and prefabricated piles, load cells can be fabricated into various shapes for application in diverse foundation types, such as diaphragm walls, caissons, etc.

Load cell of diaphragm walls

Load cell of caissons

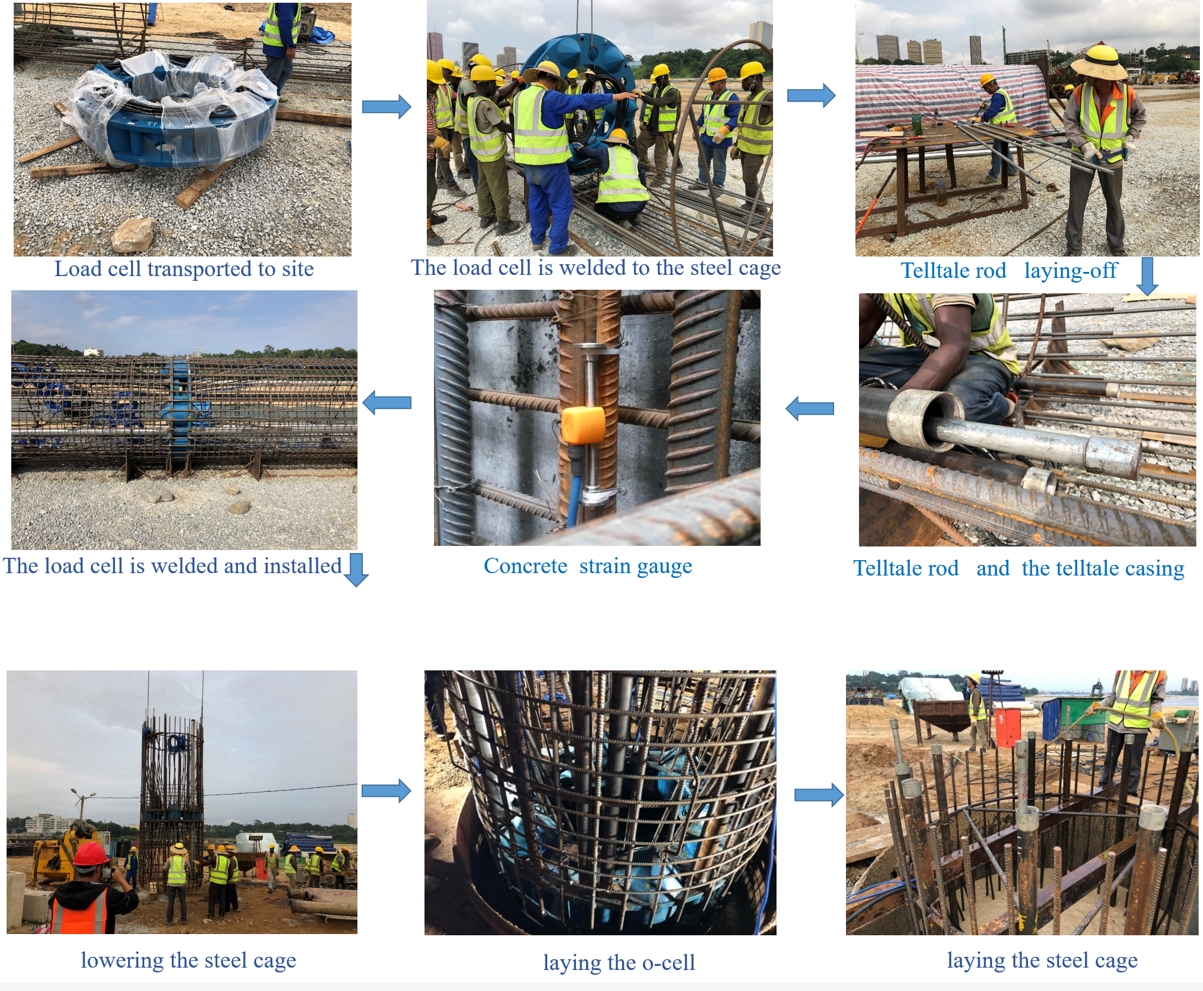

Construction and Testing Process of Cast-in-place pile

a.Construction Process

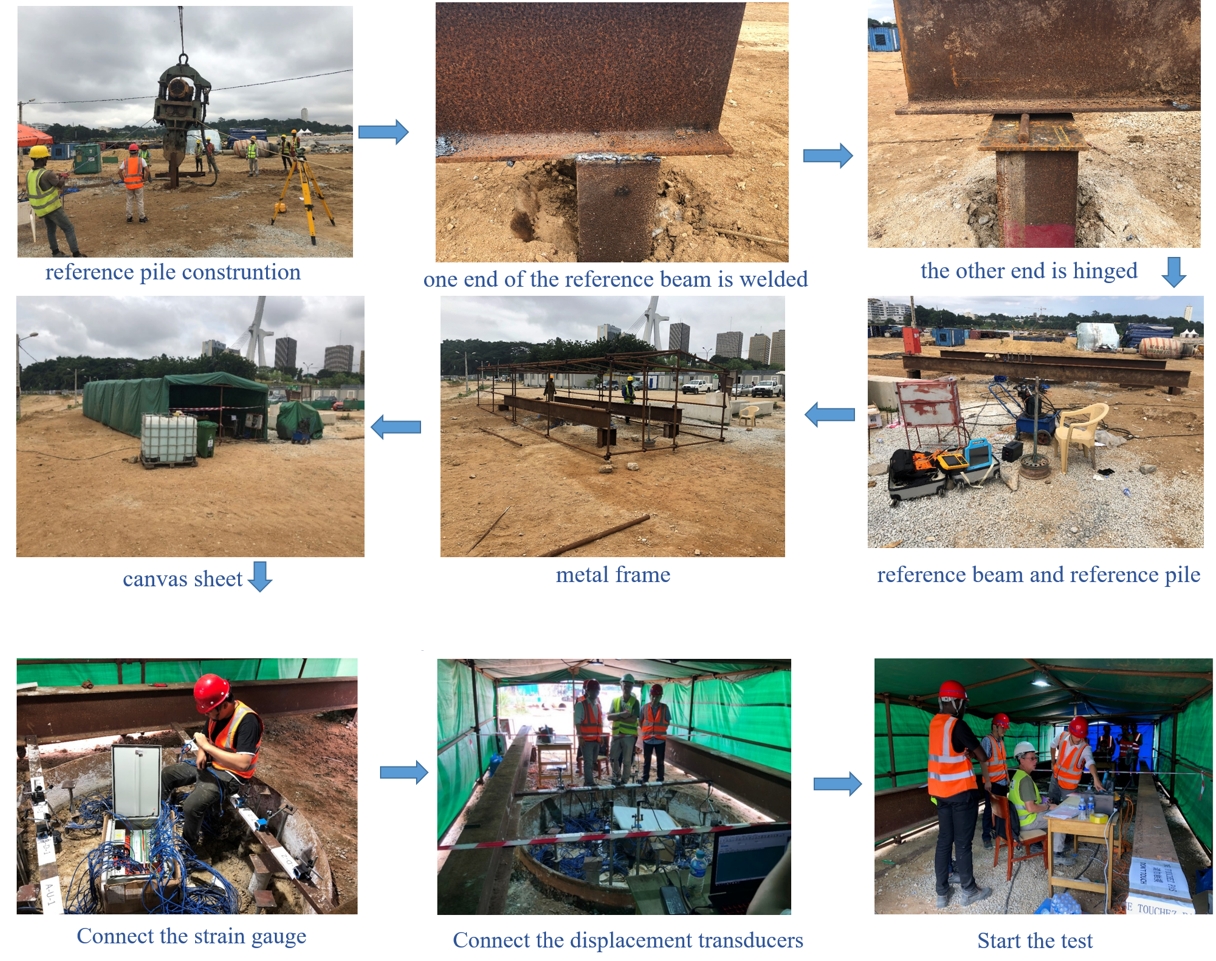

b.Testing Process

From construction completion to testing completion, the process took approximately 30 days.

For the double-load cell pile testing, tests were conducted both before and after grouting, with the entire process taking approximately 60 days.

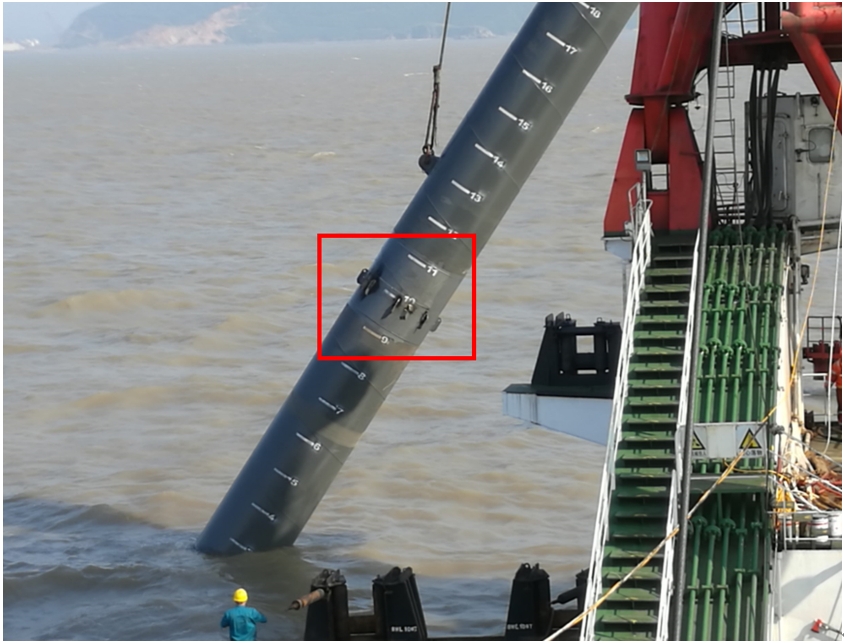

Construction and Testing Process of precast piles

Test Pile and Load Cell Hoisting

Pile driving construction

Field test

Equivalent Conversion

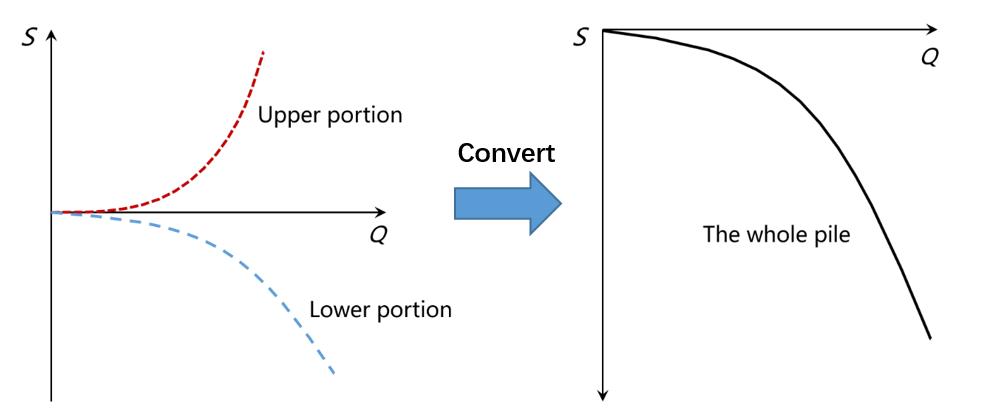

There is only one load-displacement curve for single pile in the traditional load testing which has two curves including upward and downward in bi-directional method. Hence, equivalent conversion should be made, and this is the core why it can be applied widely.

The equivalent conversion method is to convert the upward and downward load-displacement curves of the load cell measured by the static load test of the bi-directional method into the load-displacement curves of traditional top-loaded pile.

Application

Up to now, DDZPH’s bi-directional static load test has been performed in more than 1000 projects for over 8000 piles. The largest bearing capacity we tested is 314 MN, the largest diameter is 8.0 meters, and the largest length of pile has reached 126.0 meters.

Southeast University Bi-directional Static Axial Load Test Company

Southeast University Bi-directional Static Axial Load Test Company